The Role of Hydraulic Presses in Recycling Efforts

The dialogue around recycling has shifted from a murmur to a clarion call. As industries rally to the banner of sustainability, hydraulic presses are among…

Powder compaction is a process that involves the compression of powders and granules into solid forms, such as tablets, pellets, and briquettes. These solid forms are then used in various industries, including pharmaceuticals, electronics, and metallurgy. A Powder Compacting Press is the equipment used in this process. It applies a high force to compress the powder into a desired shape and size.

Powder compaction is a process in which fine grains of material in the form of powder are compressed between dies at room temperature to achieve the desired shape, and then the compressed material is heated to bond the material, also known as sintering. This process enhances the properties of the component and results in negligible wastage of raw material. The end products manufactured with this technology are used in various industries such as X-Ray machines, power tools, automobile parts, drilling machines, and grinding machines.

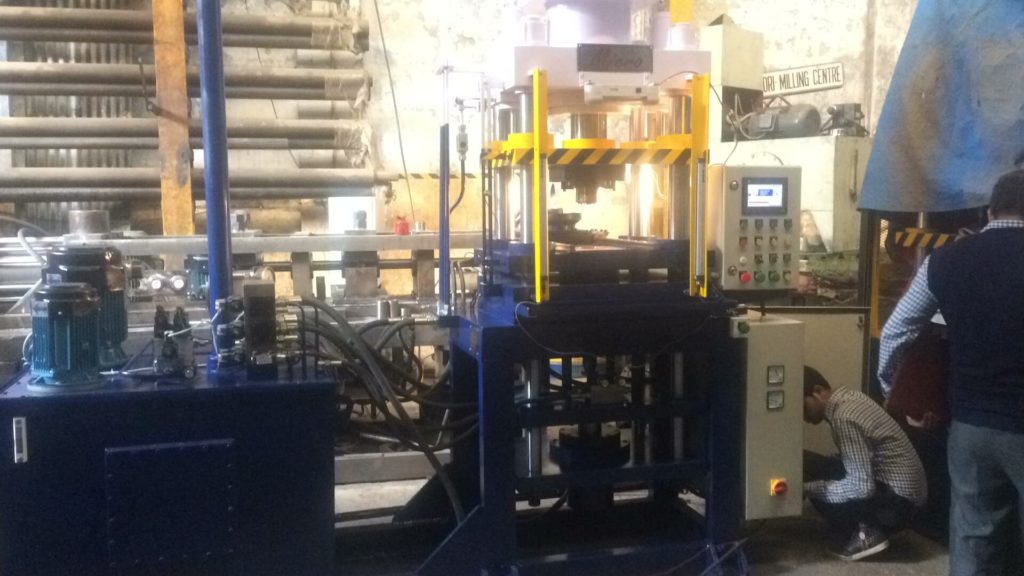

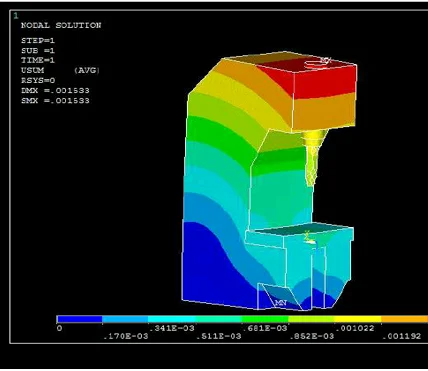

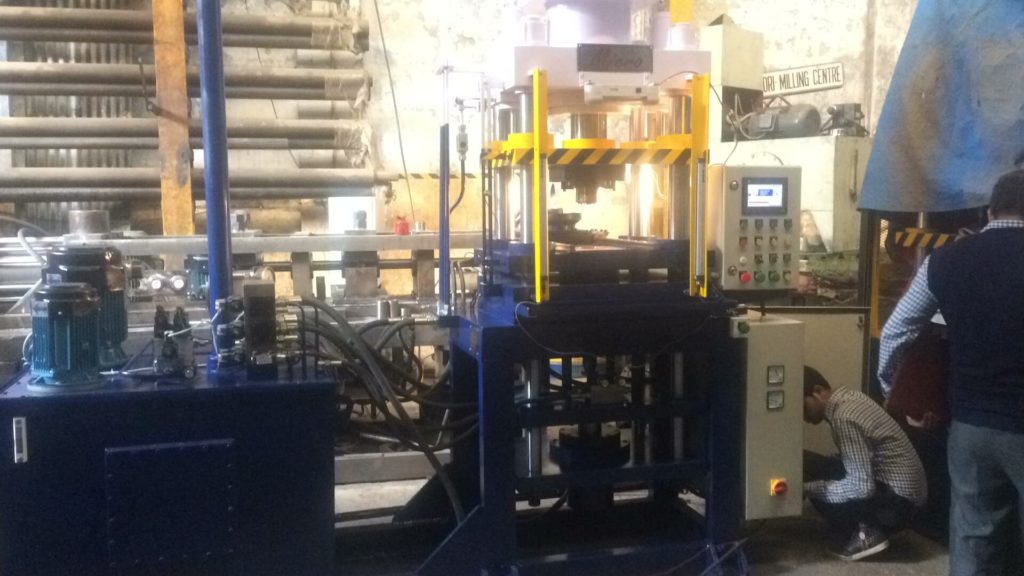

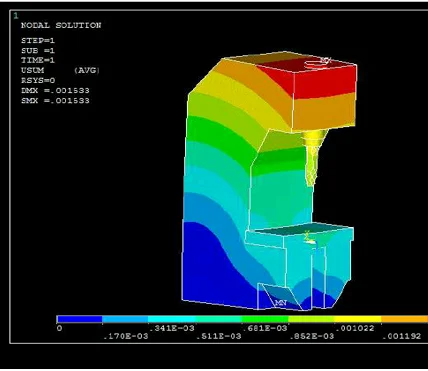

At Micro Hydrotechnic Pvt Ltd, we specialize in providing customised powder compacting hydraulic press solutions. Our indigenously designed and developed precision hydraulic press ranges from 25 to 1500 tons. Our machines are built with pillar type construction, conforming to geometrical tolerances, and meeting safety norms as per CE/OSHA requirements. We have also developed semi-automatic and fully automatic versions of our press, with a touch screen of 8-inch PLC control panels, and the option to integrate robots for pick and place of the component. Other standard features include pressure and flow control, ejection device, lubrication system, safety guards, foot switch, and peripheral equipment. Our powder compacting machines are highly recommended in the industry for their precision, efficiency, and cost-effectiveness.

Key features of a Powder Compacting Press from Micro Hydrotechnic Pvt Ltd include:

Applications of Powder Compacting Presses include:

Micro Hydrotechnic Pvt Ltd’s Powder Compacting Presses are specific to these industries as they are designed to handle the materials and meet the requirements of these industries. Our presses are engineered to maximize efficiency and productivity, reducing the time and labor required for the powder compaction process. Our presses are also versatile, can handle a wide range of materials, can process non-free flowing, abrasive or friable materials and are built to handle high-pressure compaction, when necessary.

Improving Efficiency and Precision in Pharmaceutical Production

A leading pharmaceutical company was facing challenges with their powder compaction process. They were producing tablets using a traditional mechanical press, which was slow and labor-intensive, and the final product was inconsistent in shape and size. This was leading to high material and labor costs and reduced efficiency.

To address these issues, the company partnered with Micro Hydrotechnic Pvt Ltd to upgrade their powder compaction equipment. We recommended our high-precision hydraulic press, which was equipped with automatic loading and precision compacting technology.

The new press allowed the company to significantly increase production speed while maintaining precision and consistency in the final product. The automatic loading system reduced labor costs, and the precision compacting technology ensured that each tablet was the same size and shape.

The company also saw a reduction in material costs as the new press was able to process a wider range of materials, including non-free flowing and abrasive powders.

As a result of these improvements, the company was able to meet the increasing demand for their products, reduce costs, and improve their overall efficiency. The company was very satisfied with the results and the partnership with Micro Hydrotechnic Pvt Ltd.

Powder compaction is a process in which fine grains of material in the form of powder are compressed between dies at room temperature to achieve the desired shape, and then the compressed material is heated to bond the material, also known as sintering. This process enhances the properties of the component and results in negligible wastage of raw material. The end products manufactured with this technology are used in various industries such as X-Ray machines, power tools, automobile parts, drilling machines, and grinding machines.

At Micro Hydrotechnic Pvt Ltd, we specialize in providing customised powder compacting hydraulic press solutions. Our indigenously designed and developed precision hydraulic press ranges from 25 to 1500 tons. Our machines are built with pillar type construction, conforming to geometrical tolerances, and meeting safety norms as per CE/OSHA requirements. We have also developed semi-automatic and fully automatic versions of our press, with a touch screen of 8-inch PLC control panels, and the option to integrate robots for pick and place of the component. Other standard features include pressure and flow control, ejection device, lubrication system, safety guards, foot switch, and peripheral equipment. Our powder compacting machines are highly recommended in the industry for their precision, efficiency, and cost-effectiveness.

Key features of a Powder Compacting Press from Micro Hydrotechnic Pvt Ltd include:

Applications of Powder Compacting Presses include:

Micro Hydrotechnic Pvt Ltd’s Powder Compacting Presses are specific to these industries as they are designed to handle the materials and meet the requirements of these industries. Our presses are engineered to maximize efficiency and productivity, reducing the time and labor required for the powder compaction process. Our presses are also versatile, can handle a wide range of materials, can process non-free flowing, abrasive or friable materials and are built to handle high-pressure compaction, when necessary.

Improving Efficiency and Precision in Pharmaceutical Production

A leading pharmaceutical company was facing challenges with their powder compaction process. They were producing tablets using a traditional mechanical press, which was slow and labor-intensive, and the final product was inconsistent in shape and size. This was leading to high material and labor costs and reduced efficiency.

To address these issues, the company partnered with Micro Hydrotechnic Pvt Ltd to upgrade their powder compaction equipment. We recommended our high-precision hydraulic press, which was equipped with automatic loading and precision compacting technology.

The new press allowed the company to significantly increase production speed while maintaining precision and consistency in the final product. The automatic loading system reduced labor costs, and the precision compacting technology ensured that each tablet was the same size and shape.

The company also saw a reduction in material costs as the new press was able to process a wider range of materials, including non-free flowing and abrasive powders.

As a result of these improvements, the company was able to meet the increasing demand for their products, reduce costs, and improve their overall efficiency. The company was very satisfied with the results and the partnership with Micro Hydrotechnic Pvt Ltd.

As a cosmetics manufacturer, precision and consistency is crucial for our products. Micro Hydrotechnic Pvt Ltd’s powder compaction press has been able to deliver both. The precision compacting technology ensures that our solid forms of ingredients are consistent in shape and size. The team at Micro Hydrotechnic Pvt Ltd was also very helpful in customizing the press to meet our specific needs.

We were facing challenges in producing consistent and high-quality solid forms of ingredients for our food and beverage products. Micro Hydrotechnic Pvt Ltd’s powder compaction press has helped us significantly improve our production efficiency and reduce material costs. The team at Micro Hydrotechnic Pvt Ltd was also very helpful in customizing the press to meet our specific needs.

As a metallurgy company, we deal with a lot of abrasive and non-free flowing powders. Micro Hydrotechnic Pvt Ltd’s powder compaction press has been able to handle all of our materials with ease and has improved our production efficiency. The high-pressure capability and precision compacting technology is a game-changer for our industry. I highly recommend them.

We have been using Micro Hydrotechnic Pvt Ltd’s powder compaction press for our electronic component production for the past year and it has exceeded our expectations. The fully automated system has allowed us to increase our production speed and reduce labor costs. The precision compacting technology ensures that our components are consistent in shape and size. The team at Micro Hydrotechnic Pvt Ltd is also very responsive and helpful with any issues we have faced.

Micro Hydrotechnic Pvt Ltd’s powder compaction press has been a game-changer for our pharmaceutical production. The precision and efficiency it brings to the process is unparalleled. We are able to produce a consistent and high-quality product while reducing costs. I highly recommend them.

The dialogue around recycling has shifted from a murmur to a clarion call. As industries rally to the banner of sustainability, hydraulic presses are among…

Having been on this hydraulic press journey for over 28 years at Micro Hydrotechnic Pvt Ltd, I’ve gathered a bouquet of experiences – some as…

Here at Micro Hydrotechnic, we get it – purchasing a hydraulic press represents a major investment for metal-forming shops. Naturally, you want assurance you are…

Our Powder Compacting Press is available in tonnages from 25 to 1500 Tons, with high precision and pillar type construction. The machines conform to geometrical tolerances as per JIS b 6403 and meet safety norms as per CE/OSHA requirements.

Yes, we offer the option to integrate robots for pick and place of the component.

Our Powder Compacting Press comes with a 8-inch touch screen PLC control panel, both in conventional and servo hydraulic systems.

The ejection systems available for the Powder Compacting Press include top, bottom, and auxiliary ejection options.

The frame of our Powder Compacting Press is procured from ESSAR Steel/TATA Steel, while the sealing system is procured from Parker/Merkel.

Yes, the safety of the machine and operator is taken into consideration during the manufacturing process of our Powder Compacting Press.

Ancillary equipment options such as tool lubrication devices and conveyors can be integrated upon customer request.

Our Powder Compacting Press can be used to compact materials such as graphite, friction material, sponge, explosive powder, and metal powder.

Yes, the Powder Compacting Press is designed to provide high tonnage in a small area.

Standard features of our Powder Compacting Press include pressure and flow control, ejection device, lubrication system, safety guards, foot switch, and peripheral equipment.

Each Powder Compacting Press is designed and built based on the specific requirements of the customer. This includes factors such as production capacity, the type of powder being compacted, and the available space in the customer’s factory. Our team of experts works closely with each customer to understand their unique needs and ensure that the Powder Compacting Press meets all their specifications.

Yes, our trained employees will install the Powder Compacting Press at the customer’s factory and provide comprehensive training on how to properly operate and maintain the machine. They will also be available for any further assistance or guidance the customer may need.

The lead time for delivering the Powder Compacting Press depends on various factors such as the customer’s specifications, the availability of components, and the manufacturing schedule. Our team will provide an estimated delivery time when the customer places their order.

The warranty period for the Powder Compacting Press is 12 months from the date of delivery. During this period, any defective parts will be repaired or replaced at no additional cost to the customer.

Yes, the Powder Compacting Press can be used for compacting different types of powder including graphite, friction material, sponge, explosive powder, and metal powder. Our team will work with the customer to ensure that the machine is optimized for their specific requirements.

The Powder Compacting Press requires regular maintenance to ensure that it operates at optimal performance. Our team will provide a maintenance schedule and guide the customer on the proper procedures for maintenance. In case of any technical issues, our technicians will be available for repair and maintenance services.

Yes, we do provide spare parts for the powder compacting press. We understand the importance of keeping your production line running smoothly, and we make sure that our customers have access to the spare parts they need, whenever they need them. Our trained technicians are always available to assist you in finding the right spare parts for your machine, and we keep a comprehensive inventory of spare parts in stock, so that you can get the parts you need quickly and efficiently.

The time it takes to receive spare parts for the powder compacting press will vary depending on the specific parts you need, and the location of your factory. However, we make every effort to ensure that your spare parts are delivered to you as quickly as possible. Our team of experts will work with you to determine the fastest and most cost-effective shipping options for your spare parts, and we will keep you informed every step of the way.

The compatibility of spare parts for the powder compacting press will depend on the specific model of the machine you have. Our team of experts will be able to assist you in determining the right spare parts for your machine, and we will make sure that you receive the parts that are specifically designed to work with your machine.

You can purchase spare parts directly from us for your powder compacting press. Our team of experts will be happy to assist you in finding the right parts for your machine, and we will make sure that you receive the parts you need, when you need them. If you have any questions or concerns, our team is always available to help.